So you want to organize your documents using barcodes? That is an excellent idea! Not only will it improve the speed and accuracy of your document management workflow, but it is easier to set up than it sounds.

The guide is written to give you real information instead of marketing, but you can follow the links links to read about the relevant features of Simple Index and other document management solutions on Scan Store.

Read no further! Contact our experts and we’ll configure the whole scanning process for you remotely using the demo version of Simple Index !

There are many benefits to using barcodes while scanning your documents.

Traditional scanning methods require you to scan your documents in pre-separated batches and then manually name and organize the resulting files. Barcode scanning, on the other hand, allows you to scan multiple batches in a single stack and let the software automatically name and organize the files based on the embedded barcode information. This allows you to take full advantage of your automatic document feeding scanner. After all, what’s the point of paying for a high-speed scanner if your scanning speed bottlenecks at the processing stage?

As in OCR based document scanning software, barcode scanning software uses information on the scanned images themselves to name files and place them in the appropriate folders. However, OCR can sometimes incorrectly recognize certain words and phrases, especially when you are trying to scan at lower resolutions to reduce file size and scanning time. This results in having to perform validation and correction, which slows down the process. Barcodes condense all the necessary information in a format that is much easier for computers to decipher, even at lower resolutions, with almost 100% accuracy. This allows you to reduce file size and scanning time without the cost of additional validation and correction.

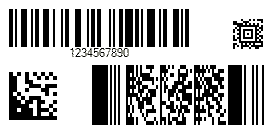

Barcodes come in many standards, but they can all be grouped into two general flavors:

1D (linear) barcodes and 2D (matrix) barcodes.

Linear barcodes are composed of parallel lines of varying widths and distances from each other, such as the UPC’s that are scanned from your purchases with a laser barcode reader at most stores.

Matrix barcodes are usually square (though sometimes circular) arrangements of smaller squares, circles, or triangles, such as the QR codes that you can scan with your phone from many modern advertisements. Matrix barcodes can pack more information per unit of area than their linear counterparts, but not all software is designed to read them.

There are both advantages and disadvantages to using one standard over

another. In addition to the amount of information that can be stored and the

capability of your particular scanning software in deciphering it, some

standards have additional functions such as checksums, which automatically

validate whether or not the barcode was read correctly. A few common standards

used in the document scanning business are listed below:

Now that you know a little bit about barcodes and why you should use them, you might be wondering how to apply them to your documents. There are a few different methods, depending on your situation.

If you can still edit the document, your best bet would be to use a special barcode font, which will allow you to type a string of characters or digits directly into a barcode format on your document using a regular keyboard. You can find many barcode fonts online for both download and purchase, with some that are purely decorative and others that match to a particular industry standard. We particularly recommend BarcodesInc.com as a source of a good free barcode font.

Often, files cannot be edited due to access, permission, or simply because they are already printed out. For instance, if you are scanning a backlog of files, it becomes difficult to add barcodes to the existing pages. Have no fear! You can still use barcode scanning by either applying barcode marked stickers, such as Avery lables, onto a blank area on the first page of each document or by printing out and inserting coversheets to separate the files.

With applications such as Simple Coversheet , you can create one-off coversheets or link it up to a data source and automate creating a separator for every customer folder in your filing cabinet.

While barcodes are naturally more accurate than text-based document management, there are still ways to ensure a higher degree of recognition. Resolution plays a part, and although barcodes are more forgiving than OCR, 300dpi is still the recommended resolution for the highest degree of accuracy. Likewise, since most barcodes encode information in the contrast between black and white areas of the page, bitonal (black-and-white) scanning is preferred over the anti-aliasing effects of greyscale and color scanning. You can also adjust the brightness and contrast options in your scanner settings to improve recognition on documents where the barcode is not being read.

The way barcodes are printed also has an effect on how easily they will be recognized. Coversheet software usually

has formatting standards built in to ensure that barcodes are printed in a way that can be recognized by scanning software.

There are both minimum and maximum sizes that barcodes can be scaled to while remaining useful – usually ranging between 80% – 200% of the suggested size. The suggested size varies by standard, but the most common width is around 1.5″. Keep in mind that there should also be at least a 0.3″ clean margin between the barcode edge and any other markings to avoid confusing the software.

The different barcode standards have varying amount of error correction built in, allowing for more and less compact barcodes with the same level of accuracy at equivalent scan settings. There are also error detection methods, such as check-sum, which act as redundancy checks by running the data through an algorithm and confirming that the result is equal to a small, easily recognized part of the barcode.

As with any automated process, barcode recognition has some limitations. Different scanning applications use different barcode recognition engines, which are the prebuilt blocks of code that perform the actual recognition. As with any software, some of these engines are better and/or faster than others at the same job, and they vary in the types of barcodes that they can recognize. You must make sure that your scanning software has the capability of accurately recognizing the barcode standards you use.

Regardless of the software that you use, image quality will play a factor. While barcodes simplify the format that data is encoded in, reducing the margin for error, degraded barcode images can still cause the engine to incorrectly read the data encoded therein. Degradation can happen digitally or physically. Digital degradation can occur when an image is shrunk to a smaller resolution and then sized back up or when an image is copied too many times and thus accrues artifacts and other transcription errors. Physical degradation can occur when a printed barcode is smeared, worn, torn, or marked upon prior to scanning. Both of these alter the contrast and precise distances between parts of the barcode that determine the data that is encoded.